Search

SEEPEX BN Pumps Boost Rock Blasting Efficiency

Smart Joint Access enables faster inspection and precise emulsion dosing

India is one of the most important markets for us globally

Piero Guizzetti, CEO, MB Crusher India

XCMG showcases ‘green’ construction equipment, electric wheeled loaders, skid steer loaders, backhoe loaders, mining loaders

China-based XCMG has showcased some of its latest products and technology during its 6th Customer Festival, including a number of alternative powered machines.

Avant launches more powerful compact wheel loaders

Avant Tecno told the media that its new compact articulated wheel loaders are among the most powerful in their size class.

We are well placed to take advantage of opportunities that India offers

Bonfiglioli India’s solutions are based on a wide range of products, including gearmotors, drive systems, planetary gearboxes and inverters. The company’s Country Manager, Kennady V Kaippally, speaks on the present size of transmission systems in India, and the segments that are driving the demand for these products.

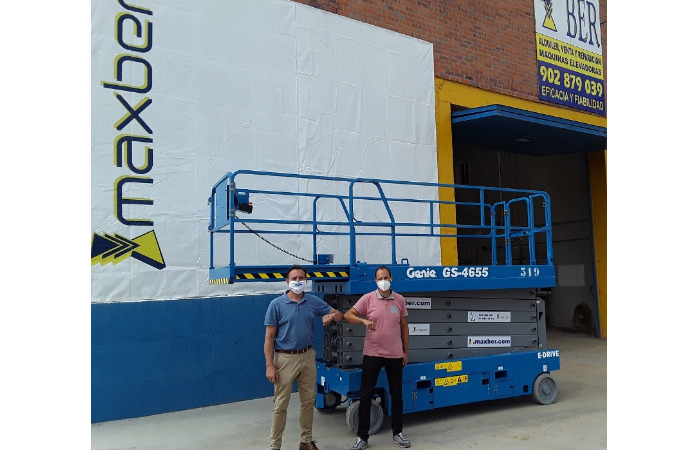

MAXBER receives Spain’s first Genie GS-4655 scissor lifts

The Spanish rental company MAXBER received two Genie® GS™-4655 slab scissor lift.

We expect a growth of 15-20 per cent after the market opens up

The foundation equipment market is driven by vibratory hammers and RCDs besides piling rigs. Surajit Mukherjee, Managing Director, Suretech Infrastructure, shares more on the market trends.

Terex AWP adds new Genie hybrid boom

Eliminating the need for customers to manage two separate fleets of machines ? one for indoors, one for outdoors ? the new Genie? Z?-45 FE hybrid articulating boom lift responds to increased demand worldwide for versatile and cost-effective ?green? access solutions in the 52 ft (16 m) range.

CRUSHING BARRIERS

Fragmented aggregate mining, as well as issues related to regulations and liquidity, are threatening the growth of the crushing and screening equipment segment in India.

Couplings for Diesel Engines

KTR Couplings (I) Pvt Ltd, established in 1998 at Bhosari, Pune is a 100 per cent subsidiary of KTR Systems GmbH Germany, a well-known name worldwide for couplings and power transmission products.

Keestrack to showcase crusher solution

Etrack will highlight its full hybrid technology with the Keestrack B4e jaw crusher and the Keestrack H4e cone crusher.

The Platform for Premieres

Comtrans 2017 has once again demonstrated its position as the leading trade fair for decision makers in the commercial vehicle (CV) and transport industry in Eastern Europe.

Blasters go hydraulic

Australian Pump Industries? range of heavy-duty hydraulic drive high-pressure cleaners with pressures up to 500 bar (7,300 psi), have played a vital role in the drilling industry.

Buoyant Future

An unprecedented and the highest-ever, $1 trillion has been earmarked for investment in infrastructure development by Government of India in the current Five-Year Plan period (2012-17). Speeding along the guidelines set forth by the government, the infrastructure construction activity is rapidly growing in roads and highways, bridges, airports and power, while realty sector is yet to catch up.

The Beginning of a Success Story

Bauer foundation piles support the glass dome of the Reichstag building in Berlin, Germany; the 828-m-tall Burj Khalifa in Dubai stands on Bauer foundation piles - Bauer has influenced specialist foundation engineering since the mid 20th Century.

On Cloud 7, Moving to 9!

The Indian construction industry is excited to witness the on-ground acceleration action in projects for most infra sectors. Probably the only sector which is waiting in the wings is realty, where there are still no signs of any major revival.

Graded Up

If tightened completion time is demanded as in the case of Delhi peripheral ring road by Supreme Court, it will sure to up the demand for advanced, high capacity motor graders.

The Grove GMK6400

Manitowoc conducted extensive `Voice of the Customer` exercises to see what users wanted most from a six-axle crane, and that research has led to the development of the award-winning Grove GMK6400.As Manitowoc looked to add a new six-axle model to its Grove GMK line

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com